2.1 Flecking

- Category: Material defect

- Sub category: Raw material inhomogenity

- Defect type: Streaking

- Defect visible after: Anodising

- Defect description:

Non uniform light and dark flecks or short streaks in the extrusion direction. The flecking is visible after the parts have been anodized.

- Defect cause:

This defect is caused by a non- uniform distribution of the iron-bearing phases in the material. Can also be due to coarse particles of of grain refiner such as TiB2.

- Defect remedy:

The defect can be reduced by improving the efficiency of the grain refinement during the casting stage of the ingots.

2.2 Grainy Appearance / Spangling

- Category: Material defect

- Sub category: Raw material inhomogenity / Extrusion defect

- Defect type: Non-uniformity

- Defect visible after: Etching / Anodising

- Defect description:

Bands of grains of different size and exhibiting pronounce preferential attack revealed by etching or anodizing. - Defect cause:

Grainy appearance is most likely controlled by the following phenomena: Amount of free zinc (Zn2+) in the etching tank (from Zn in the alloy); Grain orientation in the surface of Al profiles. Selective etching in the etching tank controlled by: Grain orientation; Selective precipitation / plating of Zn on preferential grains(depending on grain orientation and amount of free Zn) - Defect remedy:

Ensure enough additive (sodium sulphide) in the etching tank to obtain precipitation of free Zn. Optimum die design seems to be able to produce profiles with less difference in texture. In the case of 6XXX alloys ensure that Zn content is no greater than 0.03%.

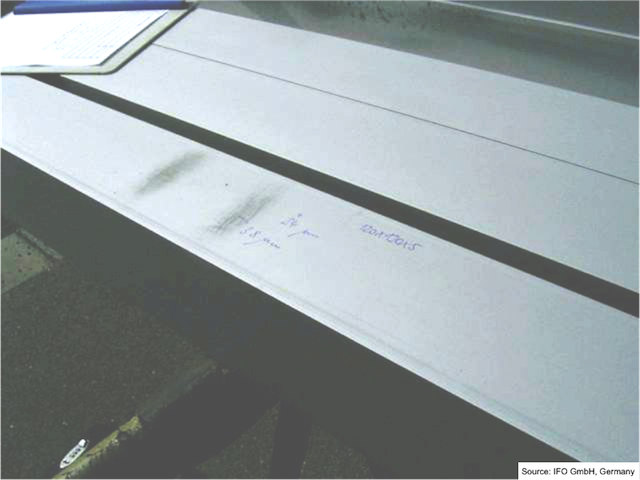

2.3 Segregational Streaking

- Category: Material defect

- Sub category: Raw material inhomogenity

- Defect type: Streaking

- Defect visible after: Anodising

- Defect description:

Segregation on specific areas of the profile, sometimes appearing as a wood grain. Segregational streaking is not visible in the extruded condition. It appears after mechanical polishing and anodizing.

- Defect cause:

Segregational streaking is caused by the preferential etching of exposed layers having different metallurgical characteristics due to ingot segregation. - Defect remedy:

Segregational Streaking can sometimes be removed by a heavy mechanical preparation. The defect can be avoided by attention to casting practices designed to minimize inverse segregation.